When most people plan a new storage system, they start with the basics: shelf height, overall dimensions, and how much storage can fit in the available footprint. But experienced architects and designers know that one factor matters just as much — shelving weight capacity.

Shelving failures rarely happen because items are “too heavy.” More often, the system simply wasn’t engineered for the load it ended up carrying. Understanding weight capacity early in the design process ensures your shelving performs the way you expect, supports the items you’re storing, and holds up over time.

The sooner you factor weight capacity into planning, the more cost-effective and resilient the entire solution becomes. This guide breaks down the core factors that influence weight capacity, how different shelving systems handle loads, and how to select the right configuration for your project with confidence.

What Determines Shelving Weight Capacity?

A shelf's weight rating comes down to a mix of engineering choices. Understanding the basics makes it easier to design systems that won't surprise you later. Here's what drives capacity in any system:

Material

Both the shelf itself and the supporting structure matter. Steel provides the highest load capacity and long-term durability, making it ideal for heavy or dense items. Wood and laminate can work well for moderate or lighter loads.

Construction

How the shelf is built is just as important as what it's made of. Welded frames are typically more resilient than bolted systems, and understructures such as channels or ribs can significantly increase weight capacity.

Shelf Span

Shorter shelves generally support more weight than longer ones made from the same material. The more distance a shelf has to cover, the more stress it takes.

Load Distribution

Even a sturdy shelf can fail if items aren’t placed evenly. A shelf rated for 300 pounds can still fail if most of that weight sits on one end instead of being spread evenly across the surface.

How Shelving Type Affects Weight Capacity

Every type of shelving carries weight differently. Materials, motion, and engineering details all influence how much a system can safely support. That’s why it’s important to look past dimensions and understand how each system manages the weight placed on it:

Static Shelving

Because static shelving systems don’t move, they generally offer higher weight capacities. With no dynamic forces to account for, engineering focuses primarily on the shelf, frame, and bracing.

Mobile Shelving

Mobile shelving (also known as high-density shelving) sits on carriages that roll along tracks, which means load capacity calculations must account for static loads, dynamic forces, and how weight shifts during movement. Because performance depends on the entire system — shelves, carriages, and rail-drive components — manufacturer guidelines are essential.

Industrial systems such as ActivRAC are engineered specifically for heavier loads. They demonstrate how mobile shelving can safely support significant weight when the full system is designed for demanding environments.

Cantilever Racking

Cantilever racking systems are built for long, bulky, or heavy items. Weight is supported by horizontal arms extending from uprights, and both arm length and arm thickness directly influence capacity. This is why cantilever is commonly used for boats, steel bars, lumber, and other oversized materials.

Widespan and Heavy-Duty Shelving

Widespan and heavy-duty shelving systems are designed specifically for dense or awkwardly shaped items. Common in industrial settings and purpose-built for higher weight capacities, these types of shelving often incorporate thicker-gauge steel, welded construction, reinforced beams, and additional bracing to manage larger loads safely.

(Some) Industries Where Shelving Weight Capacity Matters Most

Different industries place very different demands on shelving, and understanding these demands is key to specifying systems that won't fail under real-world conditions.

Museums

Museums and cultural institutions routinely store dense, high-mass objects, from stone and metal artifacts to oversized components, that create significant point loads on shelving. Because these items are often fragile and irreplaceable, weight capacity becomes a critical safety factor.

If shelving isn’t designed for the actual load, even minor failure can result in major damage. Careful planning helps ensure collections remain protected as they evolve over time.

Industrial

Industrial spaces manage a mix of heavy items, including raw materials, parts, equipment, and finished goods, all of which can place significant demands on shelving. Loads may be heavy, uneven, or subject to vibration from adjacent machinery.

When weight capacity is overlooked, the result isn’t just structural strain. It can lead to damaged inventory or downstream shipping delays.

Labs & Healthcare

Labs and healthcare spaces face a different challenge: point loads. Instruments, chemicals, and small equipment may only weigh a few pounds individually, but when grouped together, they can create concentrated forces that exceed what lighter-duty shelving is designed to support.

In these environments, a shelving failure carries a higher risk. Materials can become contaminated, equipment can be compromised, and staff may face unplanned shortages that interrupt testing schedules or delay patient care.

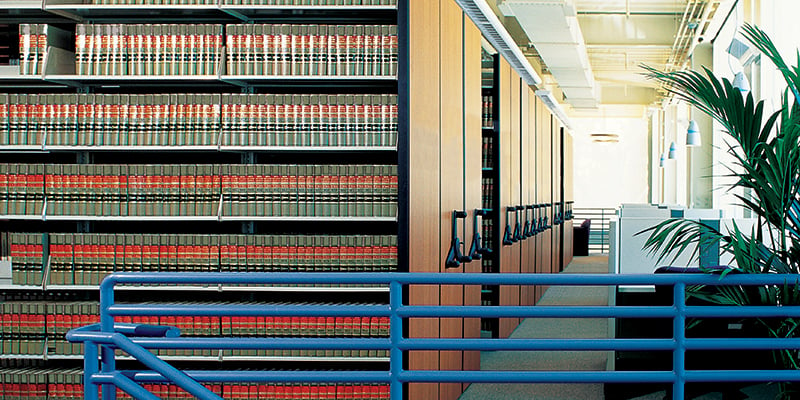

Libraries and archives, on the other hand, contend with cumulative load. Books, documents, and archival boxes may seem modest individually, but they create significant weight across long spans, especially as collections expand.

Matching Shelving to Load Demands

Selecting shelving with the right weight capacity starts with understanding the loads it will support. Whether the system will hold fully loaded boxes, individual heavy items, or smaller pieces of equipment that create concentrated loads, clarify how the shelving will be used and what kinds of materials it needs to accommodate.

Manufacturer guidelines are essential here. A shelf may be rated for 200 pounds, but that doesn’t mean the frame can support six shelves each carrying 200 pounds. Look at the system as a whole, not just individual components.

It’s also important to understand how weight ratings were measured. Some apply only to evenly distributed loads, while others account for centered or dynamic loads, or specific reinforcement materials. Point loads, such as concentrated lab equipment, can significantly change performance expectations.

Finally, factor in environmental conditions. Humidity, temperature shifts, and vibration can all affect how shelving performs. Choosing systems designed for those conditions will help ensure long-term safety and reliability.

Making Sense of Shelving Weight Capacity

Weight capacity influences everything from material choice to construction, load distribution, and overall system design. And getting it right makes all the difference in long-term performance.

If you’re evaluating shelving options and want confidence in your design and specifications, Patterson Pope’s storage experts can help. We work with you to make sure the system you select performs safely, efficiently, and exactly as your project requires.

Ready to build a shelving solution that’s engineered to hold up? We’re here when you are.